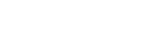

01.product description

What is Strip Pouch Packing Machine?

ODF Strip Pouch Packing Machine is designed for packaging micro-small film products.

It is suitable for items like oral instant tablets, band-aids, and similar materials.

What are the benefits of Automatic ODF Strip Pouch Packing Machine?

When you use it you will realize that the advantages of this machine include:

● The main motor can set the corresponding number of downfeeds according to the stroke length and product size.

● Each machine has an independent code, which is convenient for remote control.

● The cam box is labeled to simplify the identification of the oil type and its location.

What are the Components of Automatic ODF Strip Pouch Packing Machine?

The machine consists of various components that work together to perform the oral dissolving film packaging process.

Below are the components and their main function:

● Intelligent touch screen

The machine is equipped with an intelligent touch screen.

The touchscreen interface allows for easy and intuitive management of all packaging processes.

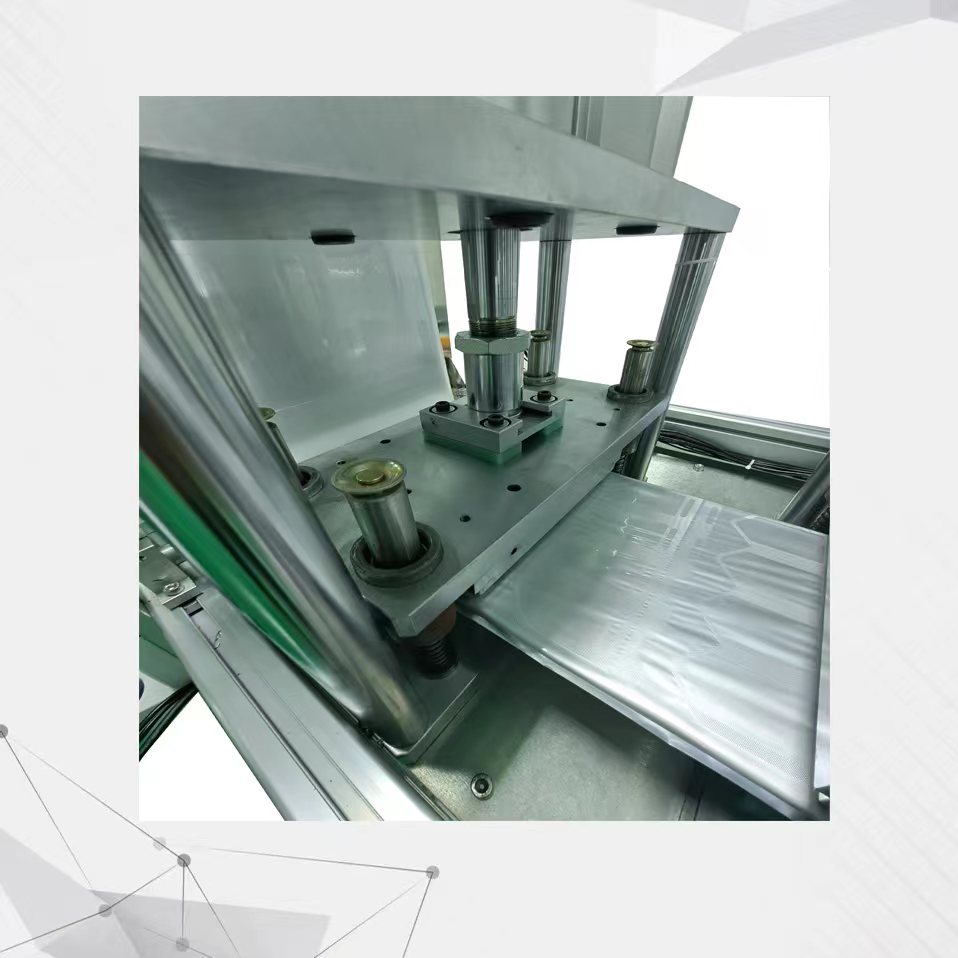

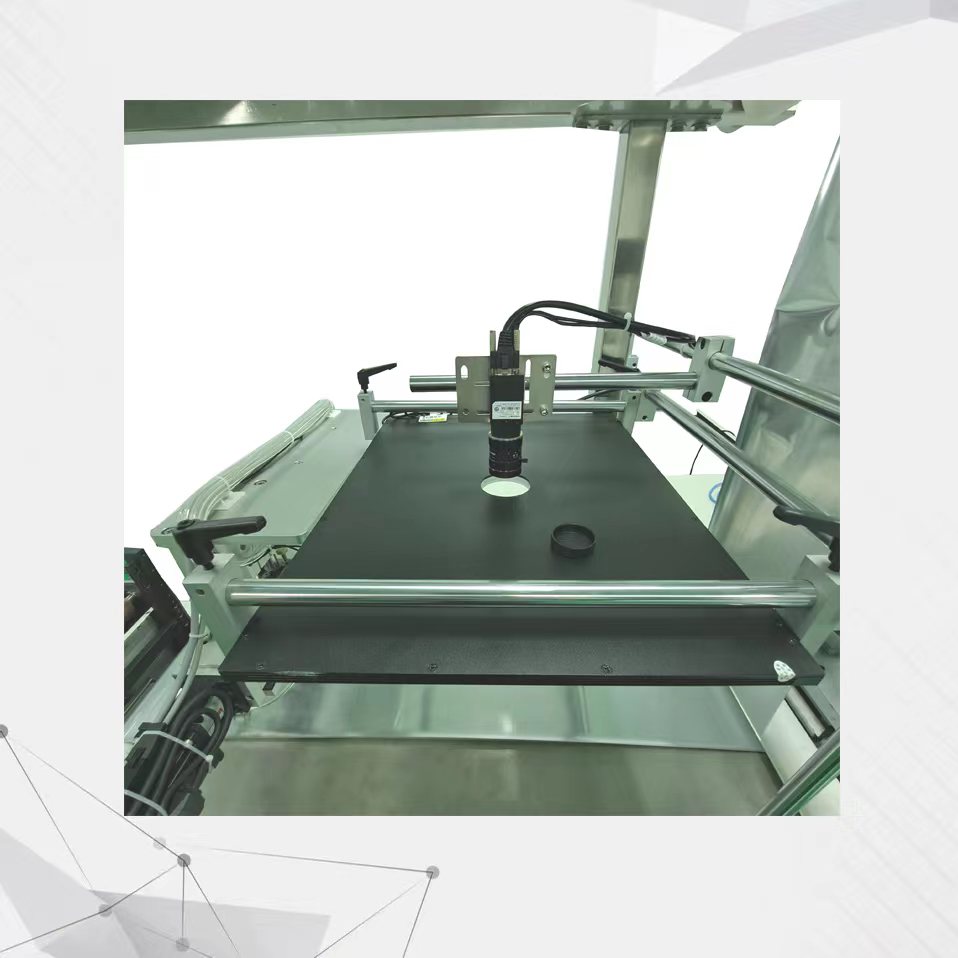

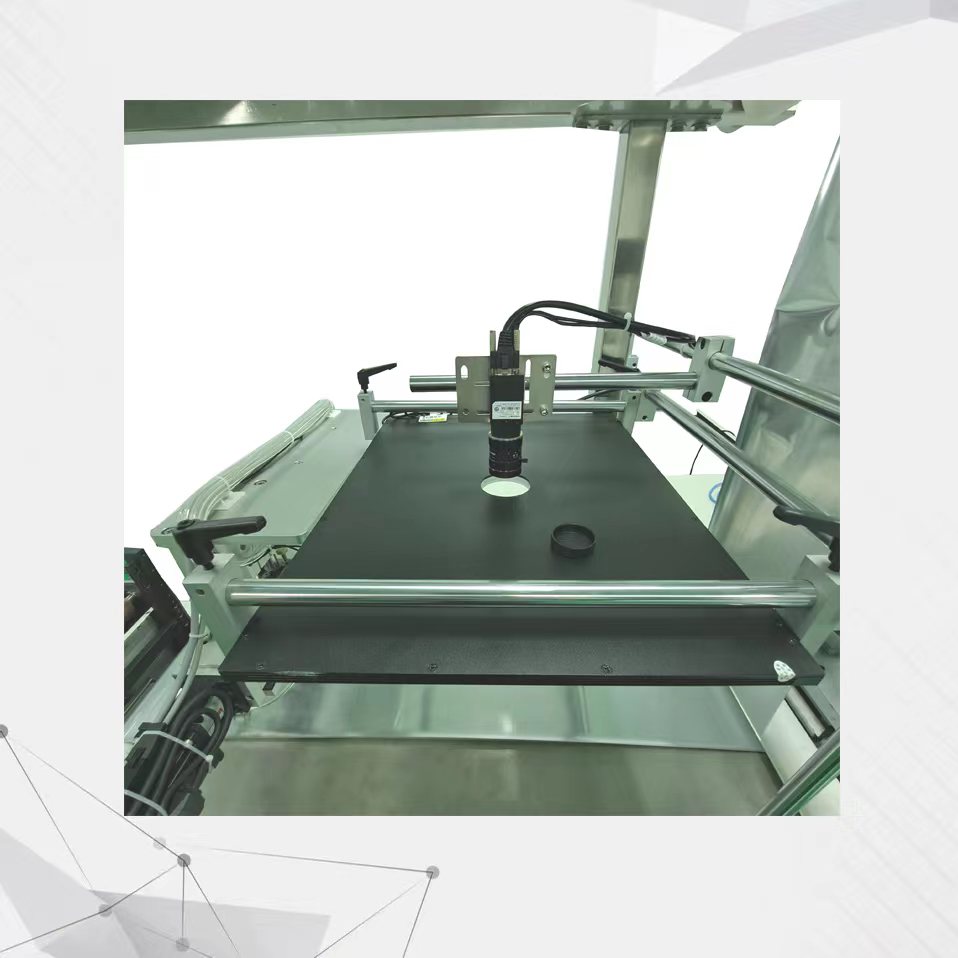

● Feeding System

The feeding system will select, position, and guide all parts.

It enables the handling and assembly of the products.

● Slitting Knife Unit

The slitting knife unit will cut the material in the packaging machine.

It has blades that perform this task.

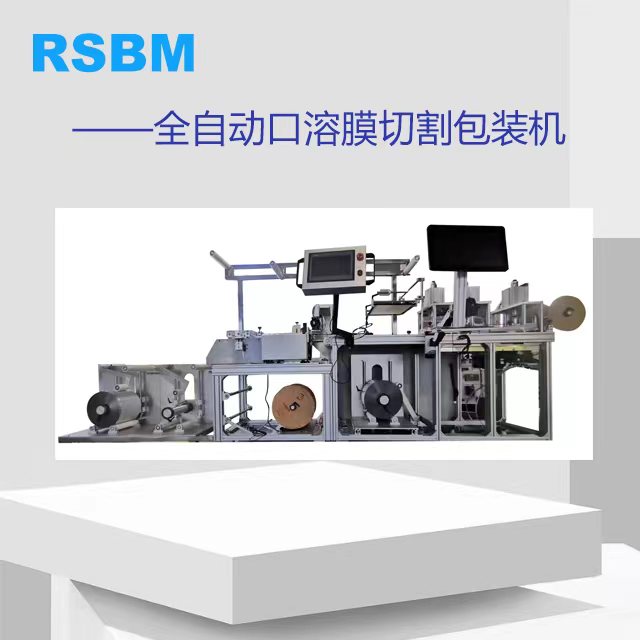

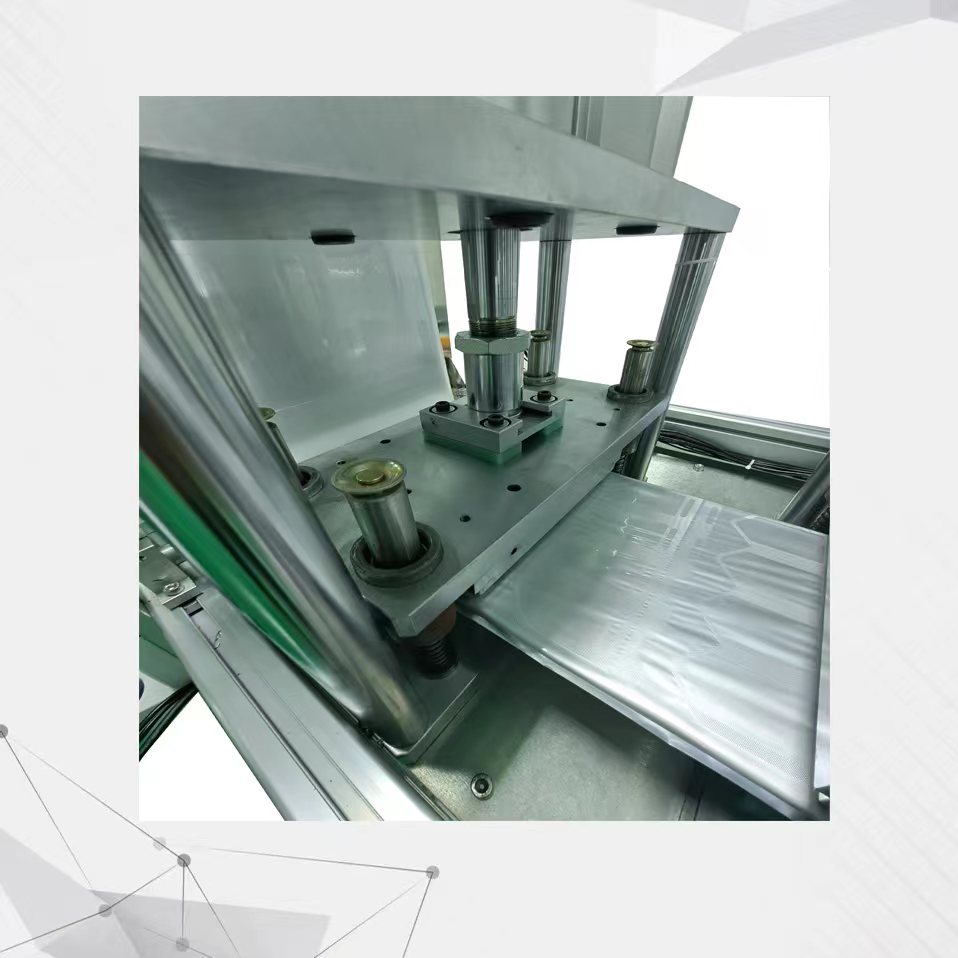

● Heat sealing system

This is the part of the packaging process that seals the filled cavities.

It contains the cam box and the bearing housing for the auxiliary heat sealing mechanism.

● Pressing Mechanism System

It presses the sealing and form material together to form a permanent seal.

What are the working principle of the Automatic ODF Strip Pouch Packing Machine?

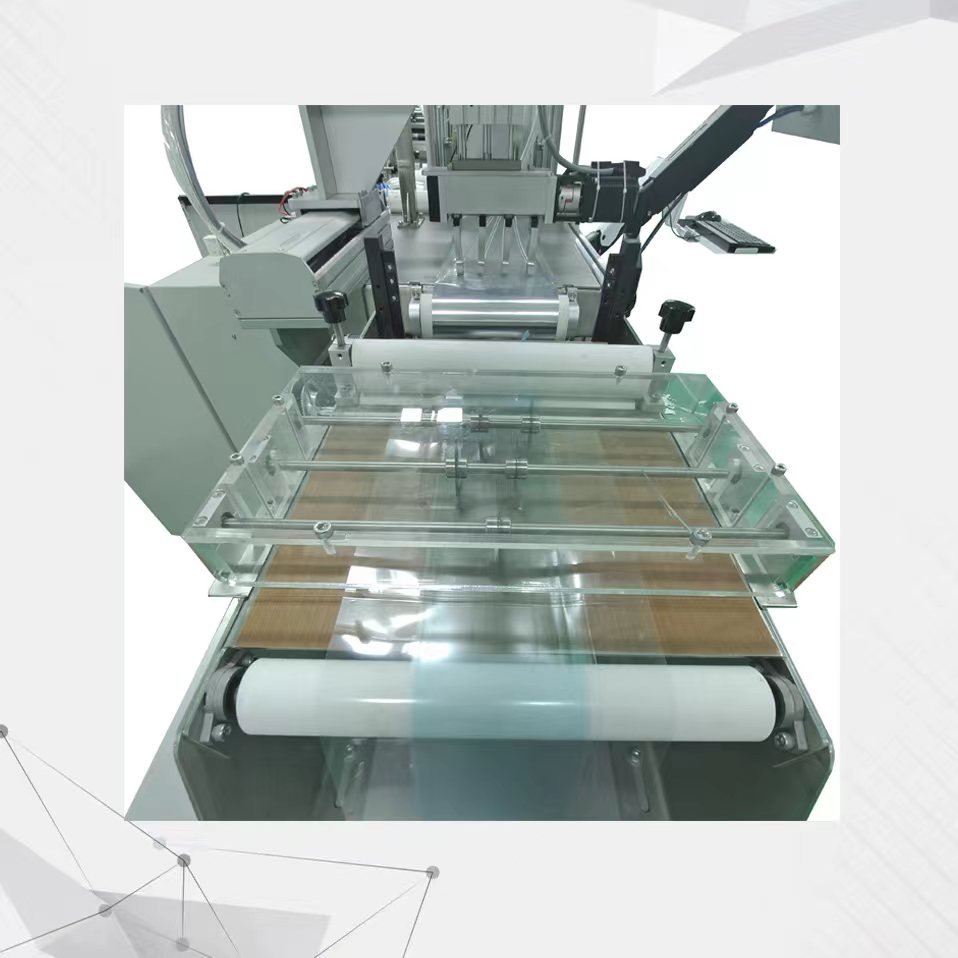

● The machine combines cutting and crosscutting operations to accurately separate the material into individual sheet products.

● It uses a sucker to accurately locate and transfer the material to the packaging film.

● The machine then performs lamination, heat sealing, and punching before finally outputting the packaged complete product.

Which Industries use Automatic ODF Strip Pouch Packing Machine?

You can use Oral Automatic ODF Strip Pouch Packing Machine for a variety of industries, for example:

● Pharmaceutical industry

This industry requires machines to package drug films, including instant oral films, and pouches for permeable films.

● Food Industry

This industry uses specialized types of machines to package films, including pouches for mouth freshening strips.

● Nutraceutical Industry

Can assist different nutraceutical companies in packaging functional food films.

Does RS provide after-sales service for Automatic ODF Strip Pouch Packing Machine?

Yes, RS offers after-sales support for the Automatic ODF Strip Pouch Packing Machine.

● After-sales warranty

We provide a warranty period to protect your rights and ensure product reliability.

Any failures during the warranty period will be repaired or replaced free of charge.

● Door-to-door installation

We support on-site installation and debugging.

Ensure proper equipment operation and desired results, tailored to your needs.

● Training courses

Our professional training courses help you and your team operate and maintain the equipment correctly.

● Parts supply

We has sufficient parts inventory to ensure that you can get the parts you need in time

● After-sales feedback

Customer satisfaction is our top priority.

We regularly communicate and seek feedback to continuously enhance our after-sales service.

Can you Integrate Automatic ODF Strip Pouch Packing Machine with other accessories?

Yes, you can integrate the Automatic ODF Strip Pouch Packing Machine with other accessories.

Some possible accessories to integrate with it include:

● Oral Dissolving Film Making Machine

● Slitting And Drying Machine

02.Technical parameters

|

Items

|

Parameter

|

|

Maximum Punching Speed(Standard 45*70*0.1mm)

|

Aluminum / aluminum 5-40 times/min |

|

Packing Film Width

|

200- 260 mm |

|

Materials Width

|

100-140 mm |

|

Heat Sealing Heating Power

|

1.5KW |

|

Total Power

|

Three-phase five lines 380V 50/60HZ, 5.8KW |

|

Air Pump Volume Flow

|

20.25m3/min |

|

Packing Material

|

Heat-seal composite film thickness 0.03-0.05mm |

|

Overall Dimensions(L*W*H)

|

3400*920*2000mm |